From the first intercontinental flight to the present day

In May 1947, a Swissair DC-4 provided the first Geneva - New York link. Seven decades later, on 14 December 2021, the East Wing dedicated to intercontinental flights came into service.

At the end of 2021, twenty intercontinental destinations (outside Europe) were served from Genève Aéroport, including 7 long-haul flights of more than five hours' flight.

A bold project for a model building

The East Wing of Genève Aéroport project is in line with the 2007-2015 master plan for the transformations of the site under the era of Robert Deillon (Director from 2006 to 2016). Its purpose is to replace wide-body buildings and walkways (Finger positions 14 15-16), and also serves positions 17-18-19. The programme includes on the tarmac, bus departures (busgate) served directly from the boarding lounges, and arrivals for buses supplying passenger transfers and returns.

This building will make it possible to manage the various flows, taking into account the security provisions, while integrating the border police checkpoints. The project also includes commercial, delivery and storage areas. The aim is to create a model building in terms of sustainable development and energy aspects, which will become the airport's showcase and brand image. The cost of the East Wing – amounting to CHF 610 million – includes the East Wing building, the customs road, demolition and construction of the GP+ (for wide-body aircraft), INAD Nord as well as the GeniLac preparatory work.

A challenge and constraints

The airport presents a particular complexity: the works must be carried out, while maintaining the platform operational. Above all, the construction of the East Wing has been a major technical challenge, with tarmac on one side and buildings very close by on the other (including Palexpo and the Arena), as well as height restrictions associated with the air traffic limit. Under the building, a road allows traffic from buses and other airport vehicles.

At all times, it was necessary to juggle the operation of the airport and its contingencies. A passage had to be guaranteed at all times for the transport of baggage to the aircraft. And finally, three positions had to remain accessible to accommodate the aircraft and their passengers. All this means that the East Wing has been built on an extremely limited surface area. Competitive ingenuity was required to circumvent the space restrictions from neighbouring buildings, and to bury part of the customs road.

The exoskeleton

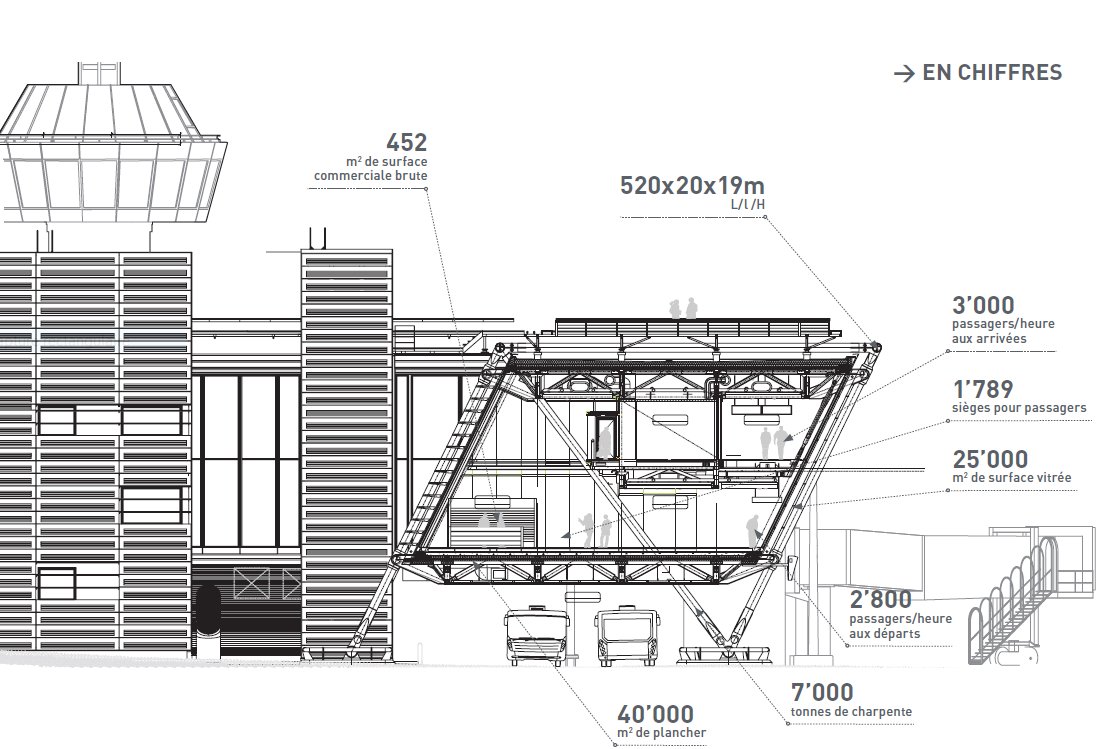

The exoskeleton, this elegant steel frame is imposing, articulated and skilfully designed. The industrial-design feet are steel parts that can withstand loads of around 550 tonnes per support. Six metres higher, paired horizontal trusses connect to the primary tubular frame and support the main floorplate. This connection resulted in the creation of a mould and various validation tests. Then, the structure rises freely to its summit, about eighteen metres above the ground, where similar beams close the structure in the transverse direction, and take up the loads of the intermediate slabs by suspension.

This is repeated every twenty metres. A huge tube highlights the entire length of this 520-metre parallelepiped. Every 80 metres, an expansion joint absorbs a movement of plus or minus five centimetres.

Transparency is almost total. This 7'000-tonne exoskeleton (the steel equivalent of the Eiffel Tower) with a simple static principle appears relatively thin compared to the overall building.

Sustainability and energy neutrality

The East Wing concept increases the airport's energy performance with the implementation of advanced technologies. The terminal’s thermal insulation is ensured using high-performance triple-glazed facades, equipped with specific sun protection for the summer months.

Electricity is produced by nearly 7’000m2 of solar panels, with some 3’400 photovoltaic panels installed. Energy neutrality is ensured with the combination of the solar power station, extensive insulation throughout the building, and high efficiency heat pumps. The latter will initially produce and store thermal energy through 110 geothermal probes. The future connection to the GeniLac network will complete this 100% renewable energy source. Even rainwater will be collected to supply non-potable water systems.

The range of materials has been selected for its durability and low maintenance. Transparent glass partitions separate the flows of travellers, maximising natural light and facilitating orientation. The ceiling is perforated with deflectors which play an important sound absorption role. Sensors have been positioned every twenty metres to monitor temperature, humidity, CO2 and volatile organic compounds (VOCs). They are linked to a building management system which ensures that the air supply and cooling/heating are adjusted, by zone, in real time. The lighting strategy has evolved over the years, replacing fluorescent bulbs with low-energy LEDs consumption.

The players

The project came about through a collaboration of companies forming the RBI-T consortium, with specialists based in three countries, the UK, France and Switzerland. Graham Stirk of Rogers Stirk Harbour + Partners is the design partner who led the team from initial ideas to completion.

Ingerop, based in Paris, has a wide range of components with particular attention to engineering. Geneva-based Atelier d'architecture Jacques Bugna and T-ingénierie played a key role in local knowledge, code compliance, contract administration and cost control.

Chronology of work

A memorable project – testimonials

Philippe Moraga, Director of Infrastructure at Genève Aéroport

« The commissioning of the East Wing is the culmination of a complex phasing that will have lasted more than ten years and which will have required covering the customs road, the construction of the temporary building of the GP+ and the relocation of existing infrastructure. Its realisation will have been a permanent technical challenge. The exoskeleton perfectly illustrates this challenge, with the design and construction of a metal structure weighing more than 7’300 tonnes. The completion of this emblematic building marks an important turning point with the realisation of the first structure that is exemplary from an energy point of view on the platform. »

Claude Vian, Head of the Major Projects Department at Genève Aéroport

« Geneva airport is often called the submarine, seen from the sky. The East Wing, on the other hand, is a huge 520m-long liner with two bridges and twelve walkways from which travellers from faraway horizons disembark and set off for other continents. Placed on the edge of the tarmac, this steel and glass hall required coordination and sustained collaboration with all internal and external services at Genève Aéroport, whether Operations, technical services, customs, concessionaires and many others. It was a daily challenge. »

Paolo Santoianni, HRS Real Estate SA, general contractor

« Four years of work, an international pandemic and the unforeseen events inherent in a project of this magnitude have made this construction a real challenge in every respect. The architectural expression strongly linked to the development of the building's techniques and statics, obliged us to pay special attention to the smallest details. In addition, airport constraints and safety processes strongly impacted the conduct of the works. This site will remain with me as a memorable experience and with great pride. »

Interview with the architect-designer Graham Stirk from Rogers Stirk Harbour + Partners

What drives you as an architect?

My motivation is a blend of architecture and engineering which represents a new form of global language of 21st century architecture. What is exciting is solving complex problems in an elegant way.

What attracted you to the East Wing project?

I liked it for its simplicity, but only in appearance, as it posed a significant technical challenge due to the many restrictions related to site constraints. We have freed up the interior volume of any load-bearing elements as much as possible in order to ensure great flexibility and to offer the passengers as unrestricted a view as possible of the runway and the Jura mountains. The absence of load-bearing elements accentuates the airy character of the composition. The intermediate slab therefore seems to float in the large volume. I love this long, simple horizontal room, this powerful composition. I also like the closeness between the passengers and the pilots: you can almost see the colour of their eyes. It is a unique and unusual experience!

This is not the first time you have worked for an airport?

No, in fact, there was Beijing Daxing Airport in 2011 during a competition, then Lyon airport (2013-2018) and the East Wing of Genève Aéroport in 2011 to 2021.

How was the notion of sustainability integrated into the East Wing project?

Achieving a sustainable positive-energy model has been an intense and iterative process, requiring close collaboration between specialists in facade engineering, mechanics and electrical installations. The chosen solution was to use triple glazing, therefore benefiting from abundant natural light. The building has many energy devices including heat exchangers, geothermal probes, a dry air cooler and a roof covered with photovoltaic panels so reducing primary energy demand. Along the East Wing technical gallery, large underground pipes have been integrated which will constitute the extension of GeniLac, an ecological thermal network. The water is captured from the depths of Lake Geneva and used as a source of cooling and heating.

What were the specific problems of the East Wing?

The restrictions related to the aviation sector as well as the proximity to existing buildings pushed us to the limit to solve complicated problems with a unique organisational diagram of the pier. This was only possible thanks to close collaboration between engineers and architects, in particular with Atelier d’architecture Jacques Bugna, T-ing Ingénierie in Geneva and Ingérop in Paris. All of this was achieved through strong team energy. Innovation is also about finding solutions to the problems that we, as architects, have created in order to realise our vision.

How will this achievement serve the image of Genève Aéroport?

It seems to me that this is above all the beauty of the construction. But it also particularly emphasises Swiss engineering. In the United Kingdom, we often favour the quality of Swiss know-how, which is of a very high standard. The East Wing is a bit like a Swiss watch whose beautifully-designed mechanism is clearly celebrated in full transparency!

The inauguration booklet

Available only in french, download the booklet or view it below: